Plastic… No thanks?

The digital CO2 footprint

August 12, 2021

Refurbishing as an answer to the chip shortage

August 12, 2021Plastic… No thanks?

Plastic is a true wonder material: it's light, cheap and easy to manufacture. Almost every product is made of plastic in some way - whether clothing, the computer, furniture or the airplane. The material paved the way for the modern consumer society and yet it brings with it many downsides.

Problems caused by plastic

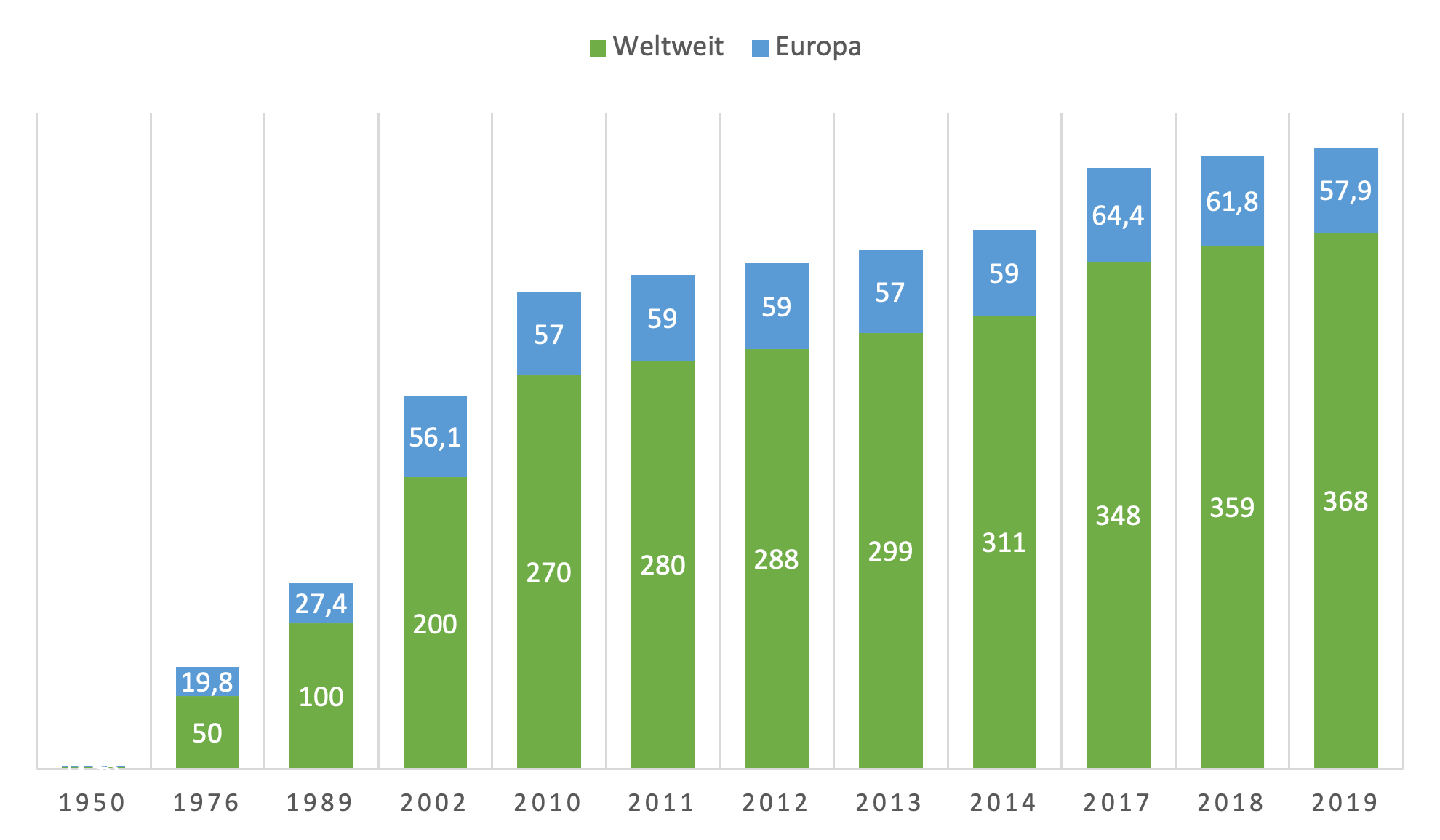

Plastics have become a cheap disposable product, contrary to the original intention of being marketed as a durable high-quality material. Since its development in 1907, a total of approximately 8.3 billion tons of plastics have been produced, and over 368 million tons of these will be produced in 2019 alone.

With a recycling rate of 52%, Switzerland is among the leaders in Europe, but recycling continues to be too low. In addition, the quota is not very meaningful, because part of the waste is exported and incinerated, but is considered recycled. The toxic toxins released by incineration pose a problem for humans and the environment. Furthermore, plastics pollute the oceans; in total, three quarters of the garbage consists of plastic. This is a constantly growing problem that costs the lives of tens of thousands of animals every year.

Fossil resources, which are needed for the production of plastics, are also becoming increasingly scarce. Since it is unknown how much crude oil is located under the earth, no exact forecasts can currently be made as to when the raw materials will run out. However, experts believe that the raw material could run out by 2050. By then, at the latest, an alternative to fossil-based plastics will have to be created.

The most sustainable alternative to plastic would of course be to do without it, but this is easier said than done. In many areas, the material is needed because of its properties.

Plastic in electrical appliances

Electrical appliances in particular benefit from the advantages of plastics and can even help save resources. Many electrical appliances feature innovative plastics that store energy and ensure less electricity is used. The ability to insulate electrical current and withstand stress makes plastics the ideal material to create a safe and efficient power supply.

In addition, the hazards associated with electricity are mitigated. In particular, as fire protection, foaming plastics can do quite a bit and are increasingly being used in vehicles or appliance enclosures as a protective function.

Computer mice made from coffee grounds

Coffee grounds can be more than just a waste product from morning coffee. In an experiment, a team of researchers from Hanover, Germany, succeeded in producing biocomposites with coffee grounds. Coffee grounds with a content of 40 percent could be added to the petroleum-based polymers. On a test basis, the composite could be used to produce computer mice.

Bioplastics from renewable raw materials

Researchers have been working on an alternative material for some time. In this context, the term "bioplastics" often comes up. But bioplastics often lead to misunderstandings. The "organic" used in this context cannot be compared with organic standards for food. The crops usually do not come from strictly controlled and certified cultivation. The required raw materials are usually grown on monocultures and treated with pesticides and fertilizers that are harmful to groundwater and soil. Predominantly, the raw materials are sugar cane, corn or potatoes. Many raw materials for bio-based plastics thus compete with the production of food, creating an ethical dilemma. Other sources of raw materials are therefore needed.

So-called drop-in solutions can already replace conventional plastics on an industrial scale. To do this, the raw material petroleum is replaced by renewable raw materials in existing processes for manufacturing plastics. Properties and chemical structure are almost identical to their petroleum-based counterparts, making them ideal for more durable products. They conserve fossil resources, but equally exhibit poor biodegradability. Few bio-based plastics can decompose, and even if they do, they require specialized industrial composting facilities because the decomposition process takes much longer than conventional compost. Furthermore, depending on their intended use, most bio-based plastics require additional additives that make recycling or the decomposition process much more difficult.

Recycling of plastics

One of the most important approaches to dealing with plastics is to feed them into the recycling loop and use them as recyclates for new products. Currently, these are still more expensive than new plastic and offer little added value for manufacturers. In 2017, the cyclos-HTP institute investigated how recyclable plastic waste is. According to the study, one-third is not recyclable at all. Only about 40 percent of the other two-thirds is reprocessed into recyclate. The majority of the waste is not reused but sent for thermal recycling. The problems for the low recycling rate are due on the one hand to the lack of recycling facilities, and on the other hand to the lack of economic and political pressure.

Conclusion

In the future, demand for bio-based plastics is expected to grow. So far, however, it is not possible to speak of an ecological advantage. They do conserve fossil resources, but they bring with them other problems. Other innovative alternatives are under development; plastics can be made from fungal spores, algae, thistles, milk or from wood. So there is no lack of innovative approaches. Whether the materials can be produced industrially on a large scale, however, is questionable.

Plastic is a material that brings many advantages, but ultimately it also causes many problems. It is not enough just to avoid plastic, rather a suitable system is needed that regulates its handling from start to finish.